We use 4 standard die casting aluminium alloys and 1 zinc alloy, which we buy solely from proven Polish and European aluminium and zinc smelters.

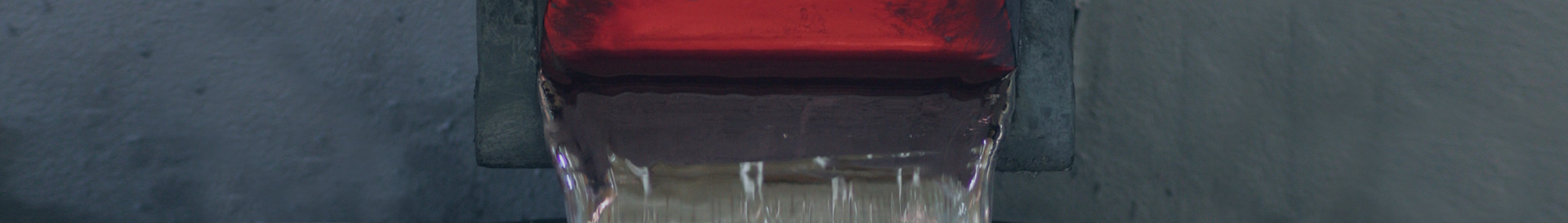

Usage of modern smelting furnaces assures high quality of molten alloy and at the same time low energy consumption and limited negative impact on environment.

Constant quality of alloys is ensured by regular spectral analyses during incoming inspection as well during production process.

ALUMINIUM

In our foundry we process as standard the following aluminium alloys: 43400, 44300, 46000, 47100 acc. EN 1676.

Where especially high requirements for tensile strength and elongation are set we use the alloy Silafont-36. Through the heat treatment of a casting made of this alloy we can achieve values of tensile strength Rm in the range of 240-350 Mpa and improved elongation from 1% to 5-15%. This allows for a reduction of the casting weight and maintaing or even improving its mechanical parameters at the same time.

ZINC

Zinc alloys are considered to be the easiest alloys to cast and generally assure a longer tool life compared with aluminum alloys. This combination makes zinc die cast parts very economical to produce.

Standard zinc alloy used by us is ZL0410 (ZAMAK 5) acc. EN 1774.

Below you can find a link to a table presenting basic properties of alloys used at LENAAL.